Needle-less valves are essential components in various medical devices, playing a crucial role in providing safe and efficient access to patients for administering medications, withdrawing blood, or delivering fluids. Ensuring their proper maintenance and cleaning is paramount in upholding patient safety and preventing infections. Here's a comprehensive guide on how to maintain and clean needle-less valves effectively.

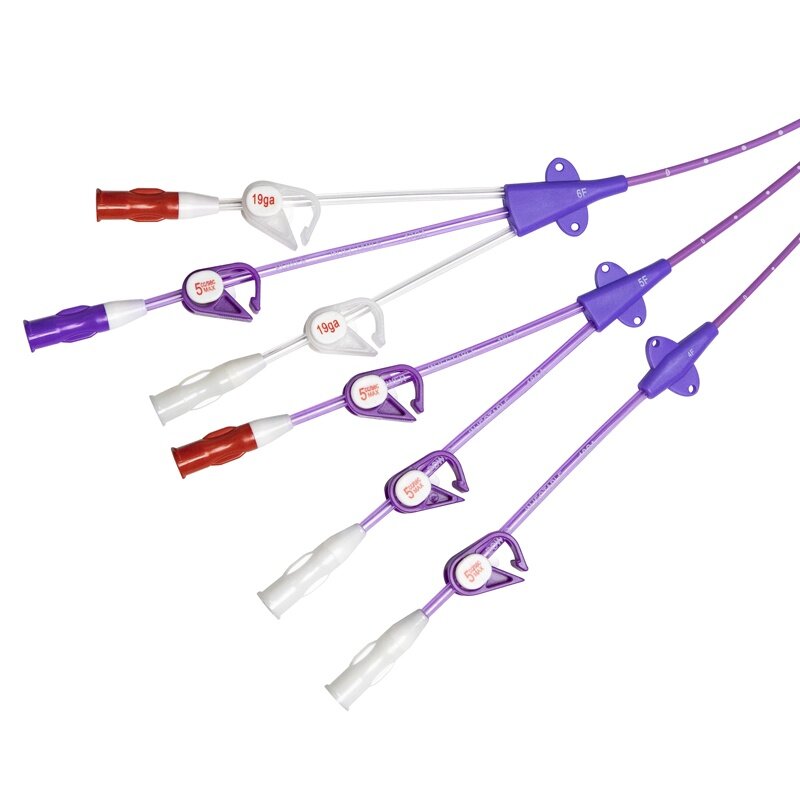

Needleless Hemodialysis Valve

Needleless Hemodialysis Valve

HealthFlow™ Needleless Valve is suitable for establishing connecting paths between infusions and infusion bottles, blood transfusion bags, and solution bags without injection needles. A needleless infusion valve can be used to connect different medical devices in the same way.

Features of Needleless Hemodialysis Valve

● Smooth surface

● Large flow rate, hemodialysis dedicated

● Straight liquid path

● Small filled cavity volume

● No metal

Benefits of Needleless Hemodialysis Valve

● Large flow rate, hemodialysis dedicated

● Reduce the incidence of infection

- SuperFlowTM Positive Needleless Valve is designed with plastic silicon split septum type instead of the traditional spring type. It could be applied for MRI without metal.

- No metal also benefits for reducing infection since no residual liquids, lipids, or blood are corroded by metal.

● Smooth surface

- Long-term indwelling will not cause indentation and compression injury to the skin

- A smooth top connector could be disinfected easily and effectively prevent bacterial implantation.

● Straight liquid path

- To ensure the integrity of drugs and blood products during the infusion process, and improve the effectiveness of treatment.

● Standard size of connector

- Link to extended medical devices with standard connectors, and connectors with screw ports make them more secure and difficult to fall off.

Importance of Maintenance and Cleaning

Proper maintenance and regular cleaning of needle-less valves are critical to prevent the accumulation of contaminants, bacteria, or microorganisms that can lead to infections or compromise the functionality of the valve. Neglecting these practices can result in blockages, reduced flow rates, or even contamination of the administered fluids, posing serious health risks to patients.

Steps to Ensure Proper Maintenance and Cleaning:

1. Understanding Manufacturer Guidelines:

Refer to the Device Manual: Follow the specific instructions provided by the manufacturer for cleaning and maintenance procedures. These guidelines are tailored to the particular make and model of the needle-less valve and should be strictly adhered to.

2. Establishing a Cleaning Schedule:

Regular Inspections: Implement a routine inspection schedule to visually assess the condition of the valve for any signs of damage, blockages, or leakage. This proactive approach allows for early identification of potential issues.

Scheduled Cleaning: Establish a regular cleaning schedule based on manufacturer recommendations and the frequency of use. Consider daily, weekly, or monthly cleaning routines depending on usage intensity.

3. Preparing for Cleaning:

Gather Necessary Supplies: Use compatible cleaning solutions recommended by the manufacturer. Ensure you have access to alcohol swabs, disinfectants, sterile wipes, and other required materials.

Follow Safety Precautions: Adhere to safety protocols, including wearing appropriate personal protective equipment (PPE) such as gloves, to prevent contamination and protect yourself from potential exposure to hazardous materials.

4. Cleaning Procedure:

Flush the Valve: Before cleaning, flush the valve with an appropriate solution to remove any residual fluids or particles.

Disinfection: Use alcohol swabs or disinfectant wipes to thoroughly clean the external surfaces of the valve, paying attention to the areas susceptible to contamination.

Allow Drying Time: Ensure adequate drying time as per manufacturer recommendations to prevent moisture accumulation, which can harbor bacteria.

5. Inspecting After Cleaning:

Check for Functionality: Post-cleaning, inspect the valve to ensure it operates smoothly without any obstruction or leakage. Test its functionality according to the manufacturer's instructions.

Record Keeping: Maintain detailed records of cleaning schedules, procedures performed, and any observations made during inspections. This documentation helps in tracking maintenance history and compliance.

6. Seeking Professional Assistance:

Service and Maintenance: Engage certified professionals or authorized service providers for periodic maintenance and servicing, especially for complex issues or repairs requiring specialized knowledge.

Conclusion

Proper maintenance and cleaning of needle-less valves are imperative to maintain their functionality and prevent potential risks to patient safety. Adhering to manufacturer guidelines, establishing regular cleaning schedules, using appropriate cleaning materials, and conducting thorough inspections are key elements in ensuring these valves remain in optimal condition. By implementing these practices diligently, healthcare facilities can significantly mitigate the risks associated with contaminated or malfunctioning needle-less valves, ultimately prioritizing patient well-being and safety.